Industry News

Jewelry Polisher Machine vs. Hand Polishing: Which Consumables Work Best?

I. Introduction: Restoring Jewelry’s Radiance

Jewelry’s sparkle can fade over time, dulled by tarnish, scratches, or wear. Whether you’re a professional jeweler or a hobbyist, a jewelry polisher—whether machine or hand-based—is essential for reviving that original brilliance. Two primary methods, jewelry polisher machines and hand polishing, offer distinct paths to a flawless finish. This article compares these techniques, focusing on the consumables that deliver the best results for each. By understanding their strengths and the right tools for the job, you’ll be equipped to make your jewelry shine like new.II. Jewelry Polisher Machines: Speed and Precision

Jewelry polisher machines streamline the polishing process, delivering efficiency and consistency, especially for large batches or tough tasks. Let’s explore the types of machines and their consumables.

A. Types of Jewelry Polisher Machines

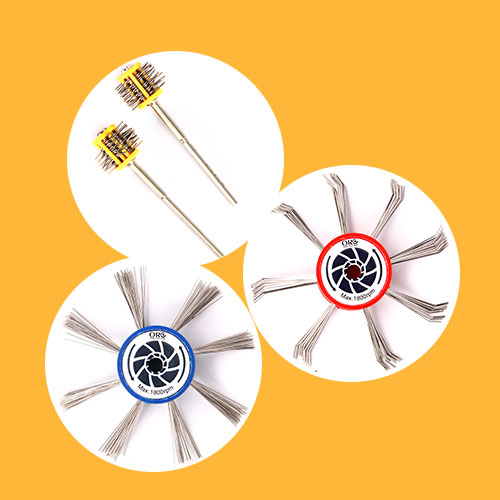

- Rotary Tools (e.g., Flex Shafts, Bench Polishers): These powerful jewelry polisher tools spin attachments at high speeds for grinding, material removal, and polishing with precision.

- Ultrasonic Cleaners: Using high-frequency sound waves in a liquid solution, these jewelry polisher machines create tiny bubbles to lift dirt, grime, and light tarnish from intricate designs.

- Tumblers (Rotary and Vibratory): As a bulk jewelry polisher, tumblers polish jewelry by tumbling it with abrasive media in a rotating or vibrating drum, ideal for cleaning and deburring.

B. Advantages of Using Jewelry Polisher Machines

- Speed and Efficiency: A jewelry polisher machine cuts down polishing time, especially for large pieces or multiple items.

- Consistency: These machines ensure an even finish across surfaces, crucial for professional or bulk work.

- Versatility: With the right attachments, one jewelry polisher machine can handle everything from heavy grinding to fine polishing.

C. Consumables for Jewelry Polisher Machines

The effectiveness of any jewelry polisher machine heavily relies on the quality and type of consumables used.

| Consumable | Description | Types/Materials | Use Case |

| Polishing Compounds/Pastes | Abrasive materials in varying grits and compositions for smoothing and finishing. | Coarse to fine grits (e.g., Tripoli, Rouge, White Diamond) | Coarse grits for material removal; fine grits for high-gloss finishes. |

| Buffing Wheels and Attachments | Wheels made of different materials to apply polishing compounds to surfaces. | Cotton, felt, wool, leather (spiral sewn, loose cotton, tapered) | Soft materials for final polish; dense materials for aggressive polishing. |

| Tumbling Media | Materials used in tumbling machines to clean and polish jewelry. | Steel shot, ceramic beads, walnut shells, organic media | Steel shot for burnishing; ceramic beads for cleaning; walnut shells for gentle cleaning. |

| Ultrasonic Cleaning Solutions | Specialized liquids for removing dirt without abrasives. | Formulations tailored to metals and soil types | Safely lifts dirt and grime without damaging jewelry surfaces. |

D. Choosing Consumables for Jewelry Polisher Machines

- Aggressive Material Removal (Rotary Tools): Pair coarse-grit compounds with firm buffing wheels for pre-polishing.

- General Polishing (Rotary Tools): Use medium-grit compounds and standard buffing wheels for a balanced shine.

- High-Luster Finish (Rotary Tools): Apply fine-grit compounds with soft cotton or flannel buffs for a dazzling result.

- Tumbling (Cleaning/Polishing): Select media like steel shot for burnishing or ceramic for deburring, based on the metal and goal.

- Ultrasonic Cleaning: Use a cleaning solution tailored to the jewelry’s metal and the type of dirt or tarnish.

III. Hand Polishing: Craftsmanship and Care

Hand polishing relies on manual techniques, using cloths, creams, and tools to restore shine. Though slower for large quantities, it excels in precision, especially for delicate or intricate pieces, serving as a gentler alternative to a jewelry polisher machine.

A. The Hand Polishing Process

Hand polishing involves applying a polishing compound or cream to a cloth or directly onto the jewelry, then rubbing gently in consistent motions. Different cloths and compounds tackle specific stages, from tarnish removal to final polishing.

B. Advantages of Hand Polishing

- Precision and Control: Perfect for detailed designs or fragile gemstones that a jewelry polisher machine might damage.

- Low Cost: Requires minimal equipment, making it ideal for beginners or small-scale work.

- Gentle Touch: Reduces the risk of harm to delicate materials or intricate settings.

C. Consumables for Hand Polishing

| Consumable | Description | Key Features | Use Case |

| Rouge Cloths | Cloths impregnated with iron oxide, designed for polishing metals like gold and silver. | Red in color; contains a fine abrasive compound. | Achieves a high-shine finish on gold and silver surfaces. |

| Microfiber Cloths | Non-abrasive cloths suitable for general cleaning and buffing. | Can be used with or without polishing compounds. | Gentle cleaning, buffing, and light polishing of delicate jewelry. |

| Jeweler’s Cloths (Two-Layer) | Dual-layer cloths: an inner treated layer for polishing and a soft outer layer for buffing. | Inner layer removes tarnish; outer layer buffs. | Polishes and buffs jewelry to a smooth, lustrous finish without scratches. |

| Polishing Creams/Liquids | Fine abrasive formulations applied directly to jewelry or cloths. | Adjustable cutting power for metals and tarnish levels. | Removes tarnish and polishes various metals (e.g., silver, platinum). |

| Polishing Papers/Sticks | Abrasive papers and sticks with graded grits for precision work. | Multiple grits for targeted scratch removal. | Polishing flat surfaces, intricate details, and eliminating fine scratches. |

D. Choosing Consumables for Hand Polishing

- Gold and Silver (Tarnish Removal and Shine): Use a rouge cloth or soft cloth with fine polishing cream designed for these metals.

- General Cleaning and Maintenance: A microfiber cloth with gentle polishing liquid keeps jewelry sparkling.

- Intricate Details and Fine Scratches: Start with fine-grit polishing papers or sticks, then finish with a polishing cloth.

- Delicate Gemstones: Opt for soft cloths and specialized creams, applying light pressure to avoid damage.

IV. Comparing Consumables: Tips for Success

Selecting the right consumables for your jewelry polisher method—machine or hand—is critical to achieving a professional finish while protecting your pieces.A. Direct Comparison of Consumables

| Feature | Machine Polishing Consumables | Hand Polishing Consumables |

| Abrasion | Variable (compounds, tumbling media) | Variable (compounds in cloths/creams/papers) |

| Application | Applied via machine action (rotation, vibration, ultrasonic waves) | Applied manually through rubbing and pressure |

| Scale | Suitable for large quantities and consistent results | Ideal for individual pieces and intricate work |

| Control | Can be less direct, relies on machine settings and technique | High degree of manual control and precision |

| Cost | Higher initial cost for machines, ongoing consumable costs | Lower initial cost, ongoing consumable costs |

B. Factors Influencing Consumable Choice

- Metal Type: Gold, silver, platinum, and brass vary in hardness. Using an incompatible consumable can scratch or dull the surface.

- Desired Finish: High-gloss, matte, or simple tarnish removal requires different grits and tools.

- Tarnish or Scratch Severity: Heavily damaged pieces need coarser abrasives initially, followed by finer ones for refinement.

C. Best Practices for Using Consumables

- Start Gentle: Begin with the finest grit or mildest compound that might work, stepping up if necessary.

- Keep It Clean: Dirty cloths or buffs can scratch jewelry. Use fresh or cleaned consumables.

- Moderate Pressure: Avoid pressing too hard, whether by hand or with a jewelry polisher machine, to protect both jewelry and tools.

- Work in Stages: For tarnished or scratched pieces, progress from coarse to fine abrasives for a smooth finish.

- Follow Instructions: Adhere to manufacturer guidelines for consumables and jewelry polisher machines to ensure safety and results.

D. Safety Tips

- Protect Yourself: Wear eye protection and a dust mask when using a jewelry polisher machine to avoid debris or dust inhalation.

- Handle Chemicals Carefully: Ultrasonic solutions and some compounds require ventilation and cautious use.

- Operate Machines Safely: Follow manufacturer instructions for your jewelry polisher machine to prevent accidents.

- Limit Skin Exposure: Prolonged contact with polishing compounds may cause irritation, so wear gloves if needed.

V. Conclusion: Your Path to a Perfect Shine

Both jewelry polisher machines and hand polishing offer effective ways to restore jewelry’s beauty, and the best choice depends on your needs, jewelry type, and expertise. For speed, consistency, and tackling heavy tarnish, a jewelry polisher machine paired with the right compounds, buffs, or media is unbeatable. For delicate pieces, intricate designs, or a hands-on approach, hand polishing with quality cloths and creams provides unmatched control.At Orobrush.com, we offer a wide range of premium jewelry polisher consumables and tools for both machine and hand techniques. Whether you need a powerful rotary jewelry polisher with the perfect compound or a gentle polishing cloth for delicate work, our products help you achieve professional results. Explore our collection to find the ideal solutions for your jewelry polishing needs.