The Best Jewelry Polishing Tools for a Pro-Level Shine

Introduction: Unlock a Dazzling Finish

Crafting a mirror-like shine on jewelry might feel like a skill only master jewelers possess. But the real secret? It’s all about the right polishing tools. At Orobrush, we believe quality tools can make anyone—seasoned artisan or eager hobbyist—achieve professional results. This guide simplifies the process, spotlighting the best tools and techniques to make your jewelry gleam with brilliance.

Know Your Metals, Choose Your Tools

Jewelry spans a range of metals—gold, silver, platinum, and beyond—each reacting differently to polishing. Picking the right tools and compounds ensures a stunning, damage-free finish.

How Different Metals React to Polishing

| Metal | Reaction to Polishing | Tool/Compound Recommendation |

| Gold | Soft, requires fine abrasives and gentle pressure to avoid scratching. Hardness varies with karatage. | Fine abrasives, soft polishing cloths. |

| Silver | Prone to tarnishing; requires more aggressive initial cleaning but shines well with the right polish and soft cloths. | Tarnish remover, soft cloths, gentle polishing. |

| Platinum | Durable and dense, requiring more robust polishing tools and compounds. | Specialized platinum compounds, durable tools. |

| Brass & Copper | Prone to oxidation; may require specialized cleaning solutions and polishing compounds. | Oxidation remover, brass/copper-specific polishes. |

| Other Metals | Stainless steel and titanium require tailored polishing tools and compounds due to their hardness and properties. | Stainless steel or titanium-specific tools and compounds. |

Pairing Tools and Polishes

The perfect tool-polish combo is key to avoiding scratches and boosting shine:- Grit Levels: Polishing compounds range from coarse (for heavy scratches) to ultra-fine (for mirror finishes). Match grit to the metal’s hardness and polishing stage.

- Chemical Match: Use polishes tailored to the metal, like tarnish removers for silver or protective coats for gold.

- Tool Fit: Ensure cloths or attachments work with the metal and polish to prevent residue or damage.

All-Purpose vs. Specialized Tools

- All-Purpose Tools: Microfiber cloths, soft brushes, and some rotary attachments handle multiple metals with the right polish.

- Specialized Tools: Cloths infused with silver-specific chemicals or platinum-grade compounds deliver tailored results.

The Spectrum of Polishing Tools: From Manual to Mechanical

Jewelry polishing encompasses a range of techniques, each utilizing different types of tools, from the simplest manual cloths to sophisticated mechanical devices.

Manual Tools: The Foundation of Fine Polishing

Manual polishing remains a cornerstone of jewelry care and achieving a professional finish, especially for delicate pieces or intricate details.

- Detailed Explanation of Polishing Cloths:

-

Tool Description Key Features Best For Microfiber Cloths Soft, non-abrasive cloths ideal for cleaning and polishing without scratching. Tight weave, lifts dirt and residue. General cleaning and applying polishes. Jeweler's Rouge Cloths Cloths impregnated with polishing compounds (e.g., red rouge for gold, white rouge for platinum). Polishing compounds for high-luster finish. Final high-luster finish, especially for gold and silver. Tarnish Removal Cloths Specially treated cloths designed to remove tarnish from metals like silver. Treated to lift and remove tarnish. Silver and tarnish-prone metals. Chamois Leather Soft, flexible material for gentle buffing and achieving a smooth shine. Very soft, ideal for a gentle buff and shine. Final gentle buff and shine. - Their Weave and Impregnation: The weave of the cloth affects its ability to grab and lift dirt, while impregnation with polishing compounds directly contributes to the polishing action. Understanding these properties allows for targeted use.

- The Importance of Hand Technique: Proper hand technique, including consistent pressure and direction of strokes, is crucial for achieving an even and streak-free finish with manual tools.

Semi-Automated Tools: Power Meets Precision

Rotary tools bring efficiency and accuracy, ideal for tougher polishing jobs.

-

Rotary Tools: With adjustable speeds, they tackle tasks from scratch removal to final buffs.

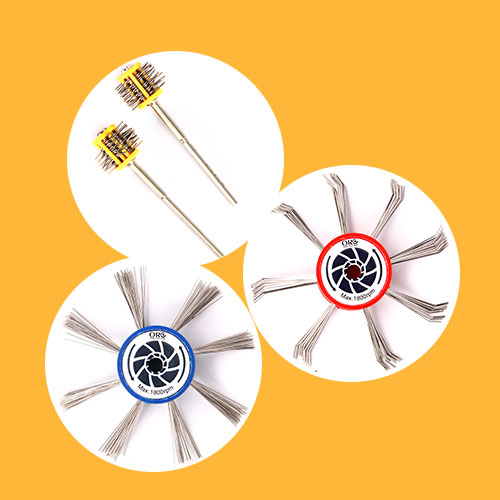

- Various Attachments:

- Buffing Wheels (Cotton, Felt, Leather): Vary in firmness for different polishing needs.

- Polishing Cones and Points: Reach tight spots or detailed designs.

- Bristle Brushes: Clean textured surfaces before polishing.

- Stay in Control: Fine-tune speed and pressure to protect delicate metals from heat or scratches.

Automated Tools: Efficiency and Deep Cleaning

Automated tools like ultrasonic and steam cleaners offer efficient solutions for cleaning and enhancing the shine of jewelry.- Overview of Ultrasonic Cleaners: These devices use high-frequency sound waves in a liquid solution to create microscopic bubbles that gently lift dirt and grime from jewelry surfaces, including hard-to-reach areas.

- Benefits: Deep cleaning, effective for intricate designs, can loosen stubborn dirt.

- Limitations: Not a substitute for polishing, may not be suitable for all gemstones (porous or soft stones).

- Overview of Steam Cleaners: High-pressure steam can effectively remove oils, residue, and polishing compounds, leaving jewelry with a brilliant final shine.

- Benefits: Excellent for final cleaning, enhances sparkle, can sanitize.

- Limitations: Requires careful handling due to hot steam, not suitable for all gemstones (temperature sensitivity).

Industrial Tools: Pro-Level Power

For high-volume or heavy-duty work, industrial machines offer unmatched efficiency.- Bench Polishers: Stationary units with powerful motors and buffs for shaping, scratch removal, and bulk polishing.

- Tumblers & Lapping Machines: Built for mass finishing or precision grinding tasks.

Pro Tips for Polishing Perfection

Mastering these tools takes practice. Here’s how to nail it:

Detailed guide to polishing tools

- Polishing Cloths: Rotate to clean cloth sections to avoid spreading dirt. Use straight, overlapping strokes with gentle pressure.

- Rotary Tools: Start at low speed, ramp up slowly, and keep moving to prevent overheating. Use the wheel’s edge for precision.

- Ultrasonic Cleaners: Stick to recommended solutions and cycles. Rinse jewelry thoroughly after cleaning.

- Steam Cleaners: Hold jewelry with tongs, aim steam carefully, and keep delicate gems at a safe distance.

Mistakes to Avoid

- Wrong Polish for Soft Metals: Match polish to metal hardness to prevent scratches.

- Too Much Force: Ease up—let the tool and polish do the heavy lifting.

- Dirty Cloths: Swap or clean cloths often to avoid reapplying grime.

- Skipping Pre-Cleaning: Polishing over dirt can embed it or scratch surfaces.

- Mismatched Attachments: Pair the right buffing wheel with the intended polish.

Secrets to a Mirror-Like Finish

- Step-by-Step Polishing: Start with a coarser compound to smooth flaws, then use finer ones for shine.

- Final Buff: Wipe with a clean microfiber or chamois cloth to remove residue and amplify sparkle.

- Even Strokes: Keep pressure and direction steady, especially by hand, for a flawless look.

- Patience Pays: A true mirror finish takes time—don’t cut corners.