Industry News

Understanding Jewelry Polishing Materials: A Guide to Techniques and Tools

The Power of Jewelry Polishing

A piece of jewelry’s sparkle is more than just surface beauty—it showcases the artistry behind its creation. Jewelry polishing is the key process that transforms rough castings into radiant treasures and revives the luster of treasured heirlooms. For jewelers and enthusiasts, understanding the tools and techniques of jewelry polishing is essential to achieving dazzling results. This guide dives into the traditional craft of manual jewelry polishing, the efficiency of modern mechanical methods, and the vital role of polishing wheels (buffs) and discs in creating flawless finishes.The Art of Manual Jewelry Polishing

Manual jewelry polishing is the cornerstone of traditional craftsmanship, relying on the jeweler’s skill and precision to bring out a piece’s brilliance.

Tools and Techniques for Manual Jewelry Polishing:

| Polishing Tool/Method | Specific Use |

| Polishing Cloths | Used for gentle cleaning and buffing, typically made of cotton, microfiber, or cloths infused with mild polishing compounds to maintain shine and remove light tarnish. |

| Polishing Compounds (Pastes/Powders) | Abrasive substances applied to cloths or jewelry surfaces to remove scratches and oxidation. Common types include rouge (for gold/silver), tripoli (general metal polishing), and jeweler’s rouge. |

| Leather Buffs | Creates a smooth surface when paired with polishing compounds, ideal for achieving a high luster on precious metals like gold and silver. |

| Handheld Brushes | Designed for cleaning and applying polishing compounds to intricate jewelry areas, ensuring detailed and uniform finishing. |

Advantages of Manual Jewelry Polishing:

- Fine Control: Manual jewelry polishing offers unmatched precision, perfect for delicate or intricately designed pieces.

- Ideal for Complex Designs: Small components or detailed patterns benefit from the careful touch of hand polishing, avoiding damage to fragile features.

- Cost-Effective Entry: Manual jewelry polishing tools require a lower initial investment, making them ideal for hobbyists or small-scale jewelers.

Drawbacks of Manual Jewelry Polishing:

- Time-Intensive: Manual jewelry polishing can be slow, especially for larger pieces or multiple items.

- Lower Throughput: Compared to mechanical methods, manual jewelry polishing isn’t suited for high-volume production.

- Skill-Dependent: A consistent, high-quality finish in manual jewelry polishing demands significant experience and effort.

The Efficiency of Mechanical Jewelry Polishing

Mechanical jewelry polishing has revolutionized the industry, delivering speed, consistency, and scalability that manual methods can’t match.

Why Mechanical Jewelry Polishing Excels:

- Faster Results: Motorized tools streamline jewelry polishing, cutting down the time needed to process large batches.

- Consistent Finishes: Properly calibrated machines ensure uniform results across multiple pieces, minimizing human error in jewelry polishing.

- Built for Scale: Mechanical jewelry polishing is perfect for mass production, meeting the demands of commercial manufacturing.

- Reduced Fatigue: Machines ease the physical strain of repetitive jewelry polishing tasks compared to manual methods.

The Role of Polishing Wheels (Buffs) and Discs in Jewelry Polishing:

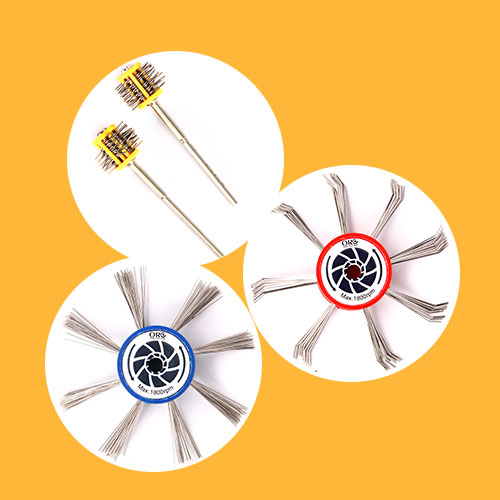

Polishing wheels (buffs) and discs are the backbone of mechanical jewelry polishing, mounted on motorized spindles and designed for specific tasks. Suppliers like Orobrush.com offer a wide range of these tools to suit various jewelry polishing needs.- Polishing Wheels (Buffs): Crafted from materials like cotton (muslin, domette), wool, felt, or synthetic fibers, buffs work with polishing compounds to smooth surfaces and create a high-gloss finish. Their weave, density, and construction vary to support all stages of jewelry polishing, from aggressive material removal to delicate final touches.

- Polishing Discs (Discs): These flat, circular tools, available in rigid or flexible forms, are designed for flat or gently curved surfaces. Coated with abrasives or paired with compounds, they ensure precise, even jewelry polishing.

Manual vs. Mechanical Jewelry Polishing: Choosing the Right Method

The choice between manual and mechanical jewelry polishing depends on the project’s scope, complexity, and goals:When to Choose Manual Jewelry Polishing:

- High-Value Pieces: For unique or costly items, manual jewelry polishing offers the precision needed to avoid risks.

- Intricate Designs: Complex geometries and fine details shine with the careful control of manual jewelry polishing.

- Restoration Work: Antique or delicate jewelry benefits from the gentle touch of manual jewelry polishing techniques.

- Small-Scale Projects: Hobbyists or jewelers with limited production volumes find manual jewelry polishing cost-effective.

When to Choose Mechanical Jewelry Polishing:

- Mass Production: Manufacturers rely on mechanical jewelry polishing for its speed and consistency in high-volume settings.

- Uniform Finishes: Machines ensure identical jewelry polishing results across large batches.

- Time-Sensitive Work: Mechanical jewelry polishing saves time, making it ideal for tight deadlines.

- Larger Pieces: Machines handle bigger items efficiently, reducing the effort required for manual jewelry polishing.